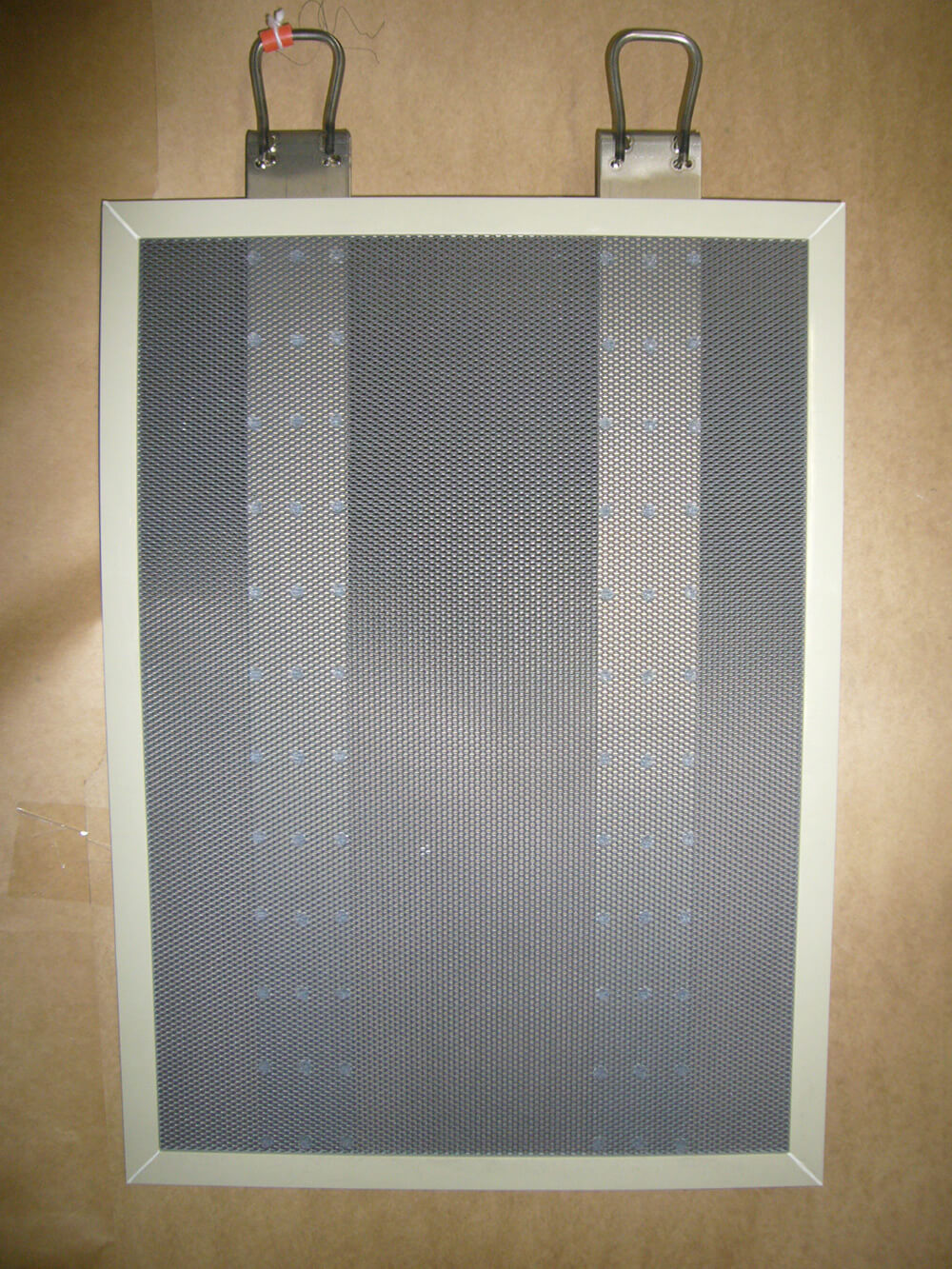

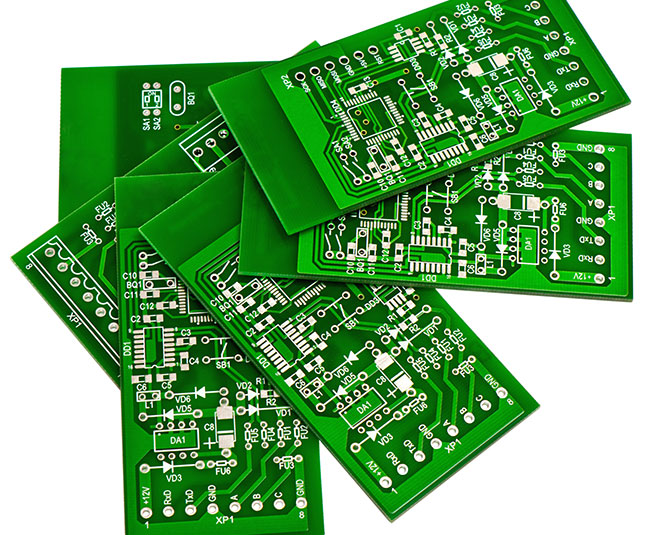

Our insoluble anodes are largely applied by leading printed circuit board (PCB) manufacturers and are selected by equipment suppliers for:

- vertical continuous plating (VCP) lines and

- horizontal electroplating equipment.

De Nora coatings, marketed under the DENORA DT brand, have been qualified by all main chemical vendors and are compatible with all plating chemicals, including the latest generation.

DENORA DT anodes are the solution for today’s challenges in the electronics industry due to:

- uniform copper deposition,

- reliable via filling ability,

- elimination of surface roughness, and

- minimum additive consumption

Uniform copper deposition, reliable via filling ability, elimination of surface roughness, and minimum additive consumption make DENORA DT anodes the solution for today’s challenge in the electronics industry.