DSA® electrodes are utilized in various electrochemical processes

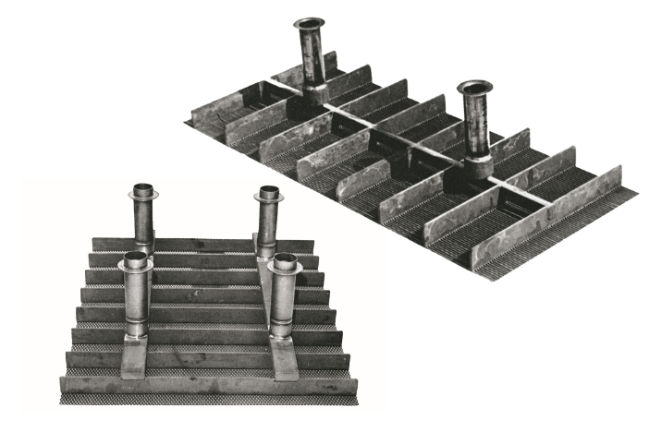

anodes-electrodes of the new DSAs®, circa 1969

DSA electrodes have a long life, ensuring excellent electrolytic performance and cell efficiency- enabling significant energy savings and optimal operating conditions. Their light and stable design allows for easy handling and application in a variety of electrochemical equipment, including those with zero electrode gap, while mitigating pollution problems derived from soluble or unstable anodes. Their designation as "dimensionally stable" reflects their ability to resist corrosion and degradation over time, maintaining both their shape and functionality.

De Nora has been a pioneer in the use of mixed metal oxide (MMO) anodes since 1969, initially to produce chlorine and caustic soda. Since then, De Nora has expanded their application to all major electrochemical processes.

Today, De Nora is a recognized specialist and industry leader in the production of mixed metal oxide DSA electrodes- a brand known and recognized worldwide with more than 60 patent families* with over 900 territorial extensions, distributed across 70 countries.

-detachable-panels.jpg)