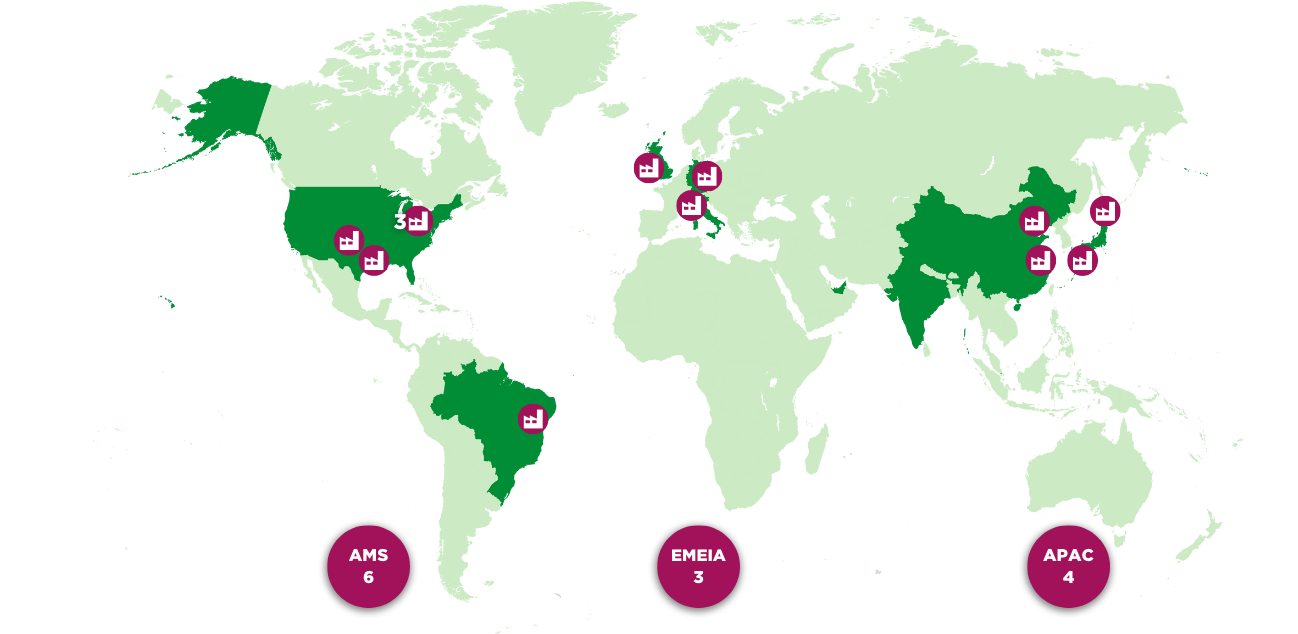

De Nora manufacturing facilities are distributed worldwide in 15 sites in Germany, Italy, the USA, Brazil, Japan, China, and India. More than 1.000 specialized workers are well trained in a high level of EHS and operational skills. De Nora's plants are certified to international quality standards and equipped with state-of-the-art coating production lines and metalworking machinery and tools.

With the largest electrodes production capacity - including advanced Gas Diffusion Electrodes (GDEs) and next-generation electrodes for new applications in renewable energy storage such as water electrolysis - De Nora is the coatings supplier of choice when it comes to industrial electrochemistry.

Manufacturing capabilities are not limited to the application of electroactive coatings: our manufacturing footprint spans from the synthesis of powder catalysts, the preparation of Non-asbestos separators for the Chlor-alkali process, the assembly of components, electrolyzers, skid-mounted systems to the assembly of proprietary water treatment equipment that are all performed within our global network of plants.

The organization of De Nora's manufacturing plants is "glocal": local experiences and centers of excellence for specific products are globally leveraged, sharing best practices across the factories' network of factories striving for practical continuous improvements.