Trusted leader in electrochemistry providing anodes for copper foil electrodeposition.

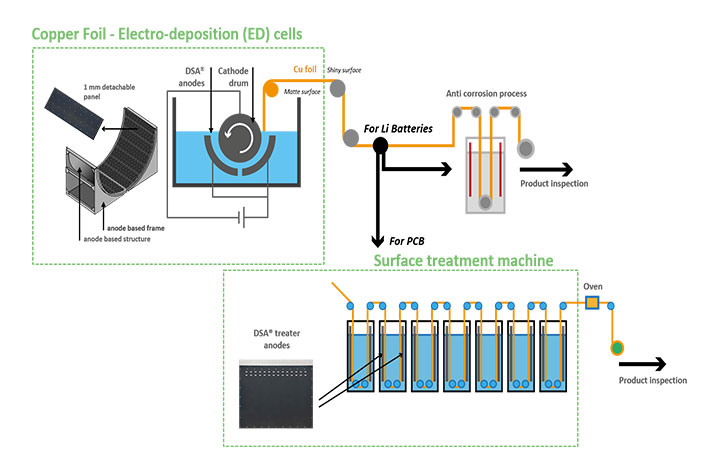

With nearly a century of experience, De Nora can support the copper foil manufacturing industry with electrodeposition cell design and electrolytic process optimization, allowing them to operate at a very reduced electrodes gap, and to produce ultra-thin copper foil.

DSA® anodes decrease cost of operation and increase efficiency for high-quality copper foil manufacturing.

We offer:

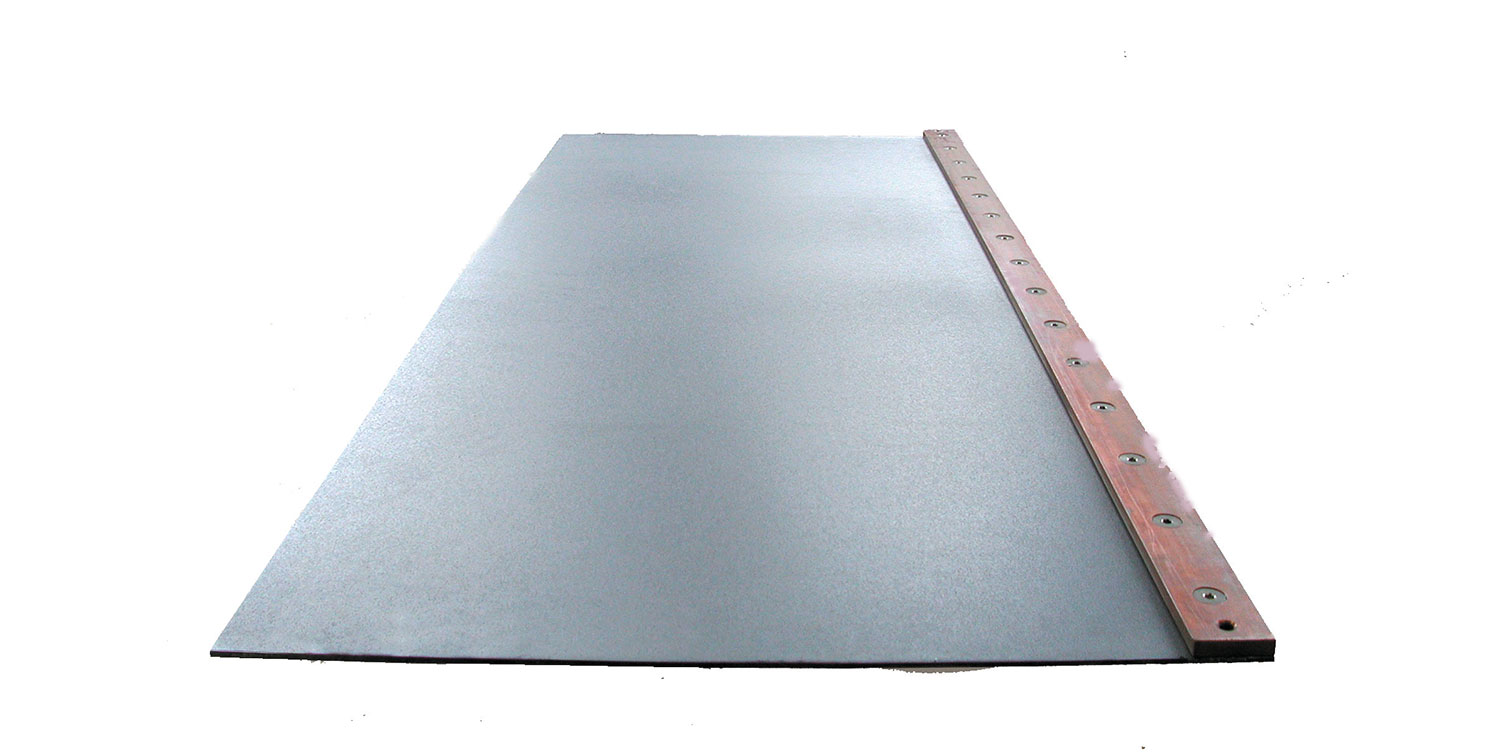

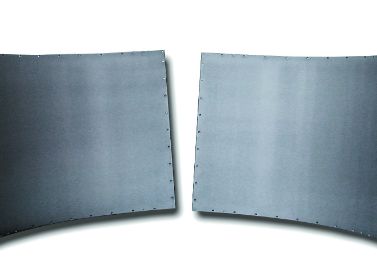

- Patented anode technologies for all electrodeposition cell designs: detachable panels, based structures, and supporting frames.

- DSA® anodes for electrochemical surface treatment of metal foil, to provide the final product attributes

- Highest level of field service and technical assistance available due to global presence

- Maintenance agreement for anodes refurbishment, recoating, repair, refreshing service for lead removal/washing (Pb washing)

- Customized offers, including leasing contracts and periodic monitoring of anodes performance

-detachable-panels.jpg)

-detachable-panels.jpg)

-detachable-panels.jpg)