CECHLO™ - MS is a safe, economical, and energy-efficient technology that poses no risks associated with delivering and storing hazardous chemicals and does not require special staff training or qualifications. De Nora’s proprietary DSA® electrode ensures reliable high performance.

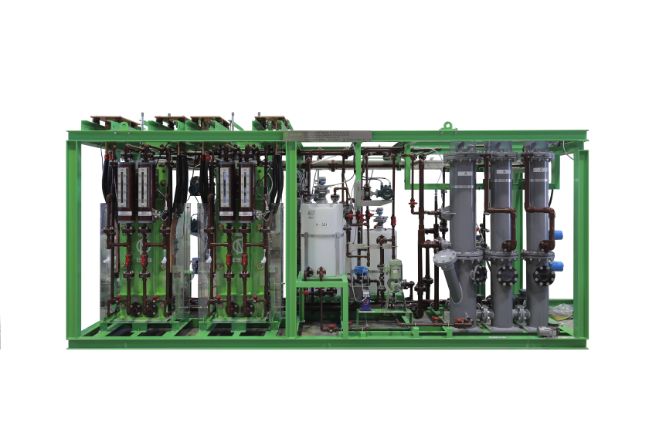

CECHLO™ - MS, On-site high-strength sodium hypochlorite generator

CECHLO™ - MS is an on-site high-strength sodium hypochlorite generator with a patented ion exchange membrane that safely produces 12.5% sodium hypochlorite, sodium hydroxide, and/or chlorine gas at the site of use. The technology is used for water and wastewater treatment disinfection, bleach manufacturing, and wholesale chemical production.

Improved Plant Safety

Advanced Engineering

Easy to Operate and Maintain

Global Support and Customer Service

Why CECHLO™ - MS technology?

- Safely and economically produces chlorine gas (Cl2) and sodium hydroxide (NaOH), or high-strength 12.5% sodium hypochlorite (NaClO), without the risks associated with the delivery or storage of hazardous chemicals such as high-pressure chlorine.

- More than 40 years of experience and improvement of ion exchange membrane electrolysis technology.

- Guaranteed performance and easy maintenance. Equipped with a complete automation control system that quickly adapts to any environment.

- Used for water and wastewater treatment disinfection, bleach manufacturing, and wholesale chemical production.

- Applied as a decentralized unit to support multiple water and wastewater treatment plants via transporting produced sodium hypochlorite.

How can we help? Contact De Nora for your water treatment needs...

CECHLO™ - MS Success Story: Hong Kong Water Supplies Department

In April 2023, De Nora successfully commissioned 20 units of CECHLO™ - MS systems at ten water treatment facilities for the Hong Kong Water Supplies Department. Watch the following video to learn more.

%20at%20Sha%20Tin%20Water%20Treatment%20Works%20with%20the%20De%20Nora%20commissioning%20team..jpg)

Photos: De Nora CECHLO™ - MS system (production capacity 2.25ton/day-Cl2) at Sha Tin Water Treatment Works with the De Nora commissioning team.

Over 400 installations worldwide

Goryeong, Korea: Goryeong Water Treatment Plant (2022)

Hongkong, China: Upgraded Disinfection for Ten Water Treatment Plants (2021)

Tokyo, Japan: Asaka Water Purification Plant (2005)

CECHLO™-MS 200 system addresses your modern-day challenges delivering values

CECHLO™-MS200 installed at Goryeong Water Treatment plant, Korea

- Improved Safety

- Significant reduction in disinfectant by-products (DBP) while

maintaining water compliance and safety

- Elimination of leakages / explosion risks during transportation and storage of bulk

liquid chlorine or hypochlorite

- Minimized safety risk for on-site personnel during operations

- Reliable and Simple Operation

- Consistent system performances over extended period

- Increased performance stability due to high quality membrane and special DSA® coatings

- Standardized, skid-mounted system with plug-and-play capability

- Simple installation and operation with reduced maintenance

- Easy integration with existing dosing systems due to same concentration of

hypochlorite and/or chlorine gas

- Minimized Total Operation Cost

- Process optimization with minimal use of salt and energy

- Significant savings in chlorine transportation and storage cost

- Minimal decay of chlorine concentration in the hypochlorite

- Improved Sustainability

- Self-sufficient chlorine supply, unaffected by shortages or price increase due to

crisis or speculation

- Reduction in carbon emissions and fuel consumption by eliminating transportation

of bulk liquid chlorine or hypochlorite

- No special drums’ requirement or container disposal for countries with regulations

on dangerous waste

- Maximized Flexibility

- Unique hybrid system enabling production of both chlorine gas and hypochlorite

How does CECHLO™ - MS technology work?

The CECHLO™ product family of electrolyzers generates sodium hypochlorite or chlorine gas (and caustic) from brine. Sodium hypochlorite is produced through an electrochlorination process that uses an electric current to convert salt water into chlorine (Cl2) and sodium hydroxide (NaOH), which is then transferred to a hypo-reactor to produce 12.5% sodium hypochlorite.

Steps in the electrochlorination process:

Technical data for CECHLO™- MS 200 series

Applications & Markets

Want to learn more about CECHLO™ systems?

Discover More

*De Nora manufactures devices for the in-situ production of disinfectants. Disinfectants can only be manufactured, placed on the market and used in the European Union exclusively on the basis of an authorization issued under Regulation 528/2012 and/or under the national legislation in force in each Member State. Contact De Nora to receive more information on regulatory compliance status of the specific equipment in your region.

Discover the Environmental Impact of Our Technology

Our comprehensive scorecard provides a clear, quantified assessment of the environmental impact of this technology.

To request your copy, please email marketing@denora.com